| |

Digital Pump Controller For Two Tank Water System |

| |

Padmansha’s digital pump manager is designed with advanced technology of microprocessor-based system. It is the safest and complete failure proof solution for long life and trouble free operations of the pumps ensuring continuous and automated water supply. Our design criterion has been built-in absolute reliability for entire life of the equipment at affordable prices. |

| |

DO YOU KNOW WHY PUMP MOTOR BURNS ? |

| |

| Over current |

Over load, voltage fluctuations, mechanical and electrical malfunctioning, phase failure (Single phasing) |

| Under current |

Dry run, reverse rotation, mechanical failure, phase failure (Single phasing) |

|

| |

WHAT CAN WE DO ? |

| |

Remember : Motor does not fail because of voltage but it burns because of current.

To Safe guard pump motor : We can monitor and control the current variation for its higher and lower allowable value.

Padmansha’s digital Pump manager positively monitors and controls current variations and safe guard’s pump set at any time of critical operation.

Digital pump manager also controls the water level in overhead tank, thus avoiding overflow. This minimizes wastage of water and electricity. |

| |

USE OF PADMANSHA DIGITAL MOTOR MANAGER |

| |

The ultimate solution of all practical problems is Padmansha’s motor manager.

- Pump is switched On & Off according to the water level in upper and lower tank.

- One of the biggest advantage is we can save electricity .

- The system gives visual indication of pump faults.

- Incorporates complex logic to control water pumps.

|

| |

OPERATION AND INSTALLATION |

| |

- Pump is switched On & Off according to the water level in the over-head and lower tank.

- The pump is started when there is water in the lower tank and the upper tank is empty.

- The pump is turned Off when the lower tank gets empty or the upper tank is full.

|

| |

| |

INSTALLATION |

| |

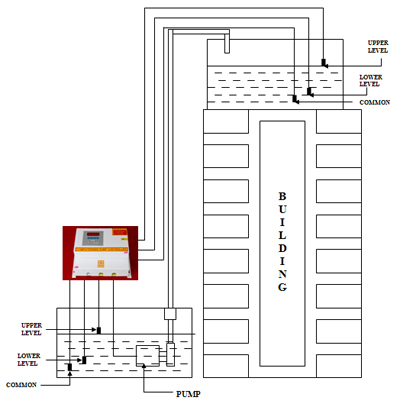

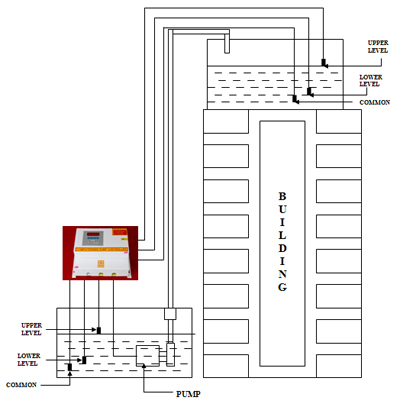

Padmansha’s digital pump manager is very easy to install and operate.

Following layout will show details of installation. |

|

| |

TWO TANK WATER SYSTEM ILLUSTRATION |

| |

FEATURES |

- Operates on two levels of the lower (Sump) and two levels of the upper (Over head) tank.

- Simple metal probes, easily available and easy to install.

- Alternating Current sensing and hence no contamination on the sensors, giving them longer life.

- No separate starter required.

- Minimum number of parts and hence less chances of failure.

- All the parts are plug-in type and hence very easy to maintain.

- Digital display of motor current, set parameters and faults.

- All the system parameters are code-locked.

- Auto / manual mode of operation.

- Protections are not bypassed even in manual mode.

- Following protections are inbuilt to the system

- Over Current

- Under Current

- Dry run

- Low voltage (Indirect Control)

- High voltage (Indirect Control)

- Single phasing preventer in case of three phase systems.

- Also available for any One tank control.

- Also available for Two pump systems with inbuilt alternating operation.

|

| |

BENEFITS |

| |

- Saves electricity and water.

- No need of manual operations saves operating cost.

- Increases motor life.

- Increase in safety.

|

| |

APPLICATIONS |

| |

Ideal for buildings with a sump storage tank and an overhead tank for water supply. |

| |

MODEL DESCRIPTION |

| |

We are providing different models of Digital Pump Manager according to different requirements. Detail description of each is mentioned in following table. |

| |

Models for

Two Tank (Over head & Sump Tank, Municipal Water Supply) Control |

| |

Model No. |

Description |

| |

|

| DPM 1(MONO.)TTC |

Single Phase Single Pump up to 2 HP for Monoblock pumps. Starter, Overload, Dry Run, Digital Ammeter, Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 2(MONO) TTC |

Single Phase Double Pump upto 2 HP for Monoblock Pumps Starter, Overload, Dry Run, Digital Ammeter, Overhead Tank and Sump Tank Control with Two level controls in each Tank, alternate Pump operations. |

| |

|

| DPM 3 TTC |

Single Phase Submersible Pump up to 2 HP with Power Relays of 25 Amp Starter, Overload, Dry Run, Digital Ammeter, Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 4 TTC |

Three Phase Single Pump upto 7.5 HP with Power Relays of 25 Amp Starter, Overload, Dry Run, Digital Ammeter, Single phasing preventer, Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 5 TTC |

Three Phase Double Pump upto 7.5 HP with Power Relays of 25 Amp Starter, Overload, Dry Run, Digital Ammeter, Single phasing preventer, alternate Pump operations, Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 6 TTC |

Three Phase Single Pump upto 10 HP Star-Delta with 3 contactor of 16 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 7 TTC |

Three Phase Double Pump upto 10 HP Star-Delta with 6 contactor of 16 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 8 TTC |

Three Phase Single Pump upto 15 HP Star-Delta with 3 contactor of 25 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 9 TTC |

Three Phase Double Pump upto 15 HP Star-Delta with 6 contactor of 25 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 10 TTC |

Three Phase Single Pump upto 20 HP Star-Delta with 3 contactor of 25 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 10 LVM TTC |

Three Phase Single Pump upto 20/25 HP Star-Delta with 3 contactor of 32 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 11 TTC |

Three Phase Double Pump upto 20 HP Star-Delta with 6 contactor of 25 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 11 LVM TTC |

Three Phase Double Pump upto 20/25 HP Star-Delta with 6 contactor of 32 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations. Overhead Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 12 TTC |

Three Phase Single Pump upto 30 HP Star-Delta with 3 contactor of 40 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer. Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 13 TTC |

Three Phase Double Pump upto 30 HP Star-Delta with 6 contactor of 40 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations. Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 14 TTC |

Three Phase Single Pump upto 40 HP Star-Delta with 3 contactor of 50 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

| DPM 15 TTC |

Three Phase Double Pump upto 40 HP Star-Delta with 6 contactor of 50 Amp Starter, Overload, Dry Run, Off Timer, On Timer, Digital Ammeter, Single phasing preventer, alternate pump operations Over head Tank and Sump Tank Control with Two level controls in each Tank. |

| |

|

|

|

| |

|

|

|